How to Manage a Distributed Remote Team Nov 23, 2024

How to Secure CRM Software and Ensure Data Privacy Sep 30, 2024

How NLP Can Transform Your Communication Skills Aug 27, 2024

Essential HVAC Maintenance for Rental Properties Aug 26, 2024

Maximizing Equipment Lifespan with CMMS Software Aug 08, 2024

Top Business Tools for Streamlining Your Operations Aug 01, 2024

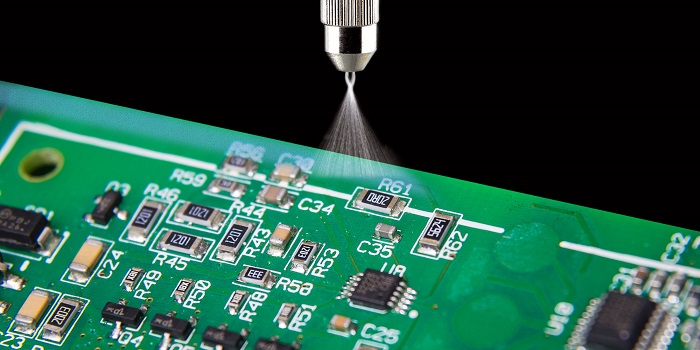

What is a Conformal Coating, and why use it on PCB?

Feb 04, 2021 12:23

In recent years, the range of electronic components has become more and more diverse. The progressive miniaturization of electronic components and circuits creates new challenges in assembly, control of electronic modules, and above all, their protection. Various methods of potting have been used for decades to protect electronic circuits. This technology is efficient, but the application of a protective coating can be cumbersome. The elimination of individual defects has led to the creation of a new technology called conformal coating.

Conformal coating is based on synthetic resins. Their main task is to protect electronic systems against the adverse effects of environmental factors such as moisture, fungi, mold, dust, corrosion, or mechanical damage. Their properties also allow you to protect the electronics against thermal shock. Conformal coatings create a safe barrier around the printed circuit board (PCB) and its components, thus minimizing the expansion of dendrites.

The technology of conformal coatings is not only a new type of protective varnishes. It is also a new method of applying and drying them. What exactly is this revolutionary formula?

Technology tailored to your needs

Conformal coatings are used for their electrical and thermal properties and application possibilities. The types of conformal coatings differ in ductility, dielectric strength, insulation resistance, solvent resistance, temperature range, and strain relief. All conformal coatings have one thing in common, though. You can easily remove them with the most common solvents and then apply a new layer.

The Electronic Manufacturing Services companies use a variety of techniques for applying protective coatings on products. The choice of application method depends on many factors. Ultimately, the method used is determined by the intended use of the PCB, the number of PCBs produced the required production speed, and the cost of the coating process. There are three primary methods of applying the conformal coating:

BRUSH APPLICATION

It’s the most straightforward technique, mainly used in repairs and alterations. This method is cheap but laborious. In the case of brush application, applying a layer of controlled thickness is very difficult. A too thin layer can significantly reduce the degree of protection. However, a too thick one can lead to cracks in the varnish. However, brush application is successfully used in small-scale productions, most often after repairs.

SELECTIVE MACHINE APPLICATION

Selective machine application consists of applying a protective coating to appropriately selected components of the printed circuit. The protective coating is applied using a properly designed machine. Thanks to this solution, it is possible to cover individual elements with an even layer of varnish of an appropriate thickness. The selective application is used especially for large and repetitive items. It guarantees speed and precision. However, this method is not simple and requires the supervision of a qualified operator.

SPRAY APPLICATION

Spray application is a method in which varnish is applied to a printed circuit by spraying. The application of the coating in small-lot production is usually performed manually in a specially prepared spray booth. The spray application also can be automated. That reduces the need for masking and allows you to get a repeatable process. Spray application is one of the most economical and convenient methods of applying coatings.

Automated methods certainly speed up the process of protecting PCBs. However, the final choice of application method is not evident. Electronic manufacturing services specialists analyze the design in detail each time to determine the best solution. Knowledge of the individual types of applications allows them to identify the most cost-effective and qualitative conformal coating method and material for a given project. The correct application can significantly improve the performance of the coating and the entire PCB.

Why are conformal coatings used on PCB?

Conformal coatings are attractive in terms of technology and price, as they are the alternative to the classic technology of encapsulation of electronic circuits. There are four classes of conformal coatings: Acrylic, urethane, silicones, and varnishes. Although each material has its own specific properties, all conformal coatings share at least ten beneficial properties in common. These properties make them increasingly used in PCBs:

1. Long service life

2. Non-Toxicity

3. Low viscosity, comparable to water

4. Good adhesion to various types of materials

5. Temperature resistance

6. Resistant to liquids and moisture

7. Breathability

8. The lightness of the layer

9. Fast-drying properties

10. Low price

CONFORMAL COATING APPLICATION REQUIRES CLEANLINESS

Coating suppliers recommend pre-washing and drying the boards before painting. This is a key condition for protection to be reliable. Unfortunately, many companies, in order to avoid costs and save time, do not pay attention to the cleanliness and dryness of PCBs before application. The surface should also be free from external materials. If this extremely important element is neglected, it is almost certain that coating defects will appear. Thus, it will not protect the electronics properly.

Conformal coating outsourcing

Reliability is paramount in modern electronics. PCB protection is essential. Due to the difficulty of selecting a coating material, internal technological constraints, and increasing client requirements, original equipment manufacturers (OEMs) are increasingly choosing to work with electronics manufacturing service (EMS) providers. Collaboration with an expert allows OEMs to reduce initial operating costs and eliminate subsequent, unforeseen expenses.

The protective coating is to protect the PCB and its components against adverse external factors. Conformal coatings are applied where high performance and reliability are required. However, the material itself is not everything. Only the right material and the correct application guarantee maximum protection of electronic components.

For more information, see: https://asselems.com/

Let’s be honest; OTT platforms have completely changed our movie-watching experience and made entertainment just a click away. A few years ago, who would have thought that watching regional or international movies could be this easy, convenient, and tailored to our budget and preferences? And, yet here we are enjoying the options of Marathi, Malayalam, Hindi, Gujarati, Tamil movies, and a lot more at our fingertips. Read more

Electronic Logging Devices (ELDs) have revolutionized the trucking industry by streamlining logging practices and ensuring compliance with federal regulations. Designed to monitor a vehicle’s engine and automatically record driving hours, ELDs replace traditional paper logs and provide an efficient solution for tracking Hours of Service (HOS). If you're looking to complement your fleet's technology, partnering with tools like a reliable truck dispatch service can further optimize operations and keep your business running smoothly. Read more

The HONOR Magic 7 Pro price in ksa makes it an appealing option for those looking for a high-end smartphone. This advanced device stands out with its sleek design and robust build quality. This blog delves into the details, examining what makes the HONOR Magic 7 Pro unique, from the materials used to its overall durability and user experience. If you’re considering purchasing a high-end smartphone that balances aesthetics and functionality, this review of the HONOR Magic 7 Pro’s design and build quality will provide you with all the information you need. Read more

TECH NEWS

Jan 11, 2025 14:55

Copyright © Fooyoh.com. All rights reserved. User Agreement | Privacy Policy | Contact us

| Advertising

| About us

| Careers