Things to consider when buying laser marking machine

Sep 01, 2020 06:28

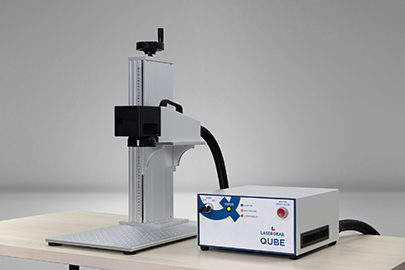

Laser marking is all about labeling different types of objects with the help of a laser. The basic of laser marking involves altering the optical appearance of any surface using a laser beam. Hence purchasing a laser marking machine is all about making a crucial decision for your business. The hispeed laser marking machine makes use of high-powered lasers to engrave different types of designs on different kinds of surfaces.

Given the different kinds of lasers and materials needed, choosing the best laser for marking may be tough. In order to make the right choice, a person should be well-aware of the specs of laser marking and the properties of the materials needed. Here are some factors to consider when buying laser marking machine.

Materials

Every machine is designed to work well with a specific kind of material. The decision to purchase the machine depends on the requirements of the company will have from it. Hence, you should make sure that whatever your needs are, they are fulfilled by the device. Next, choose the kind of material you need to do the engraving on.

Budget

Apart from your purpose, your budget decides the kind of machine you should go for. However, one should allow the cost to dictate the quality. You should have a pre-decided amount before you purchase a machine that cuts through different types of materials with precision. There may be an affordable model available, but you may have to spend a lot on power later. Hence your overall cost will increase in the long run.

Maintenance

Maintenance is a major element to be taken into consideration when purchasing a laser engraving machine. You should find out about the maintenance required for a particular machine and whether it can be done in-house or by the hands of professionals. If it is a tough task, then you may have to hire a technician for it, which would increase the cost.

Hence, you should look out for a Hispeed laser markets manufacturer who can render after service for your device. As the machine will work daily, it is important to select the one with top quality to meet your requisitions.

Engraving speed

The engraving speed can be compared to the optical fiber power source, the higher the power, the more is the speed. Going for a 10W optical fiber will give you a speed of 4000mm per second offering a poor result while a 30W laser can engrave a depth of 0.3mm which is higher than 4000mm per seconds giving a better result.

Work area

Another major point to consider is the work area. The factor is all about the size and the number of pieces to be worked upon. It is important to find out if the device has an automatic change that can streamline the finish and add to your production time.

We at HiSpeed Laser System are the best Hispeed laser markers manufacturer offering superior quality materials. To know more about our products, visit our website.