Adapt to Change with SCADA Systems' Flexibility

Aug 08, 2023 14:46

Supervisory Control and Data Acquisition (SCADA) systems are an essential element of industrial automation, designed to perform three primary functions - supervision, control, and data acquisition. SCADA system typically comprise an architecture consisting of one or more computers dedicated to supervisory tasks as well as human-machine interface implementation (HMI), peripheral devices like Remote Terminal Units (RTUs), I/O modules and Programmable Logic Controllers (PLCs) connected with process machinery, as well as communication networks that facilitate proper data exchange between these peripheral devices and supervisory computers.

One of the primary advantages of SCADA systems is their flexibility. Thanks to their modular and adaptable structure, SCADA software enables companies to adapt to changing business conditions more easily in a globalized market environment. SCADA software features development tools that allow modification of SCADA applications to connect new devices across different transmission media and protocols.

Flexibility is especially crucial in today's fast-paced industrial environment, where companies must quickly adapt to changes in market conditions, technology advancements, and regulatory requirements. A flexible SCADA system enables these companies to quickly modify processes or add machinery or sensors as needs evolve, or adjust operating parameters as required to keep pace with changing requirements.

Pro of Scada Systems

SCADA systems (Supervisory Control and Data Acquisition) have revolutionized industrial automation and process monitoring, offering numerous advantages as well as drawbacks. One key benefit is providing real-time monitoring of various distributed devices within an industrial infrastructure - helping optimize operational efficiency, increase productivity and lower labor costs while decreasing labor costs overall. SCADA systems also facilitate collection and analysis of large amounts of process data that facilitate better planning as well as fast response to anomalies or failures in processes.

SCADA Systems and Company Growth

As businesses expand, their processes may become more intricate. A flexible SCADA system can adapt with them as their needs change by adding or altering components as required.

Example: A company may begin by installing a simple SCADA system to control a single production line. As it expands, adding more production lines, its SCADA system can easily adapt. Should it later decide to automate some manual processes, its SCADA system can easily adapt so as to accommodate its new automated machinery.

SCADA Systems and Technological Advancements

In addition to supporting company growth, SCADA systems can also adapt to technological advancements. As new technologies emerge, companies can modify their SCADA systems accordingly to take full advantage of them.

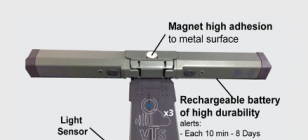

As cloud applications have become more prevalent, SCADA technologies have evolved towards integration with the Internet of Things (IoT). SCADA systems can expand IIoT capabilities; by merging both technologies together companies can achieve much quicker, more detailed, and safer collection and verification of company data.

Conclusion

SCADA systems offer great versatility, making them adaptable to company growth and technological developments. This adaptability makes SCADA systems ideal for today's fast-paced industrial environment where companies must quickly respond to changes in market conditions, technological innovations, and regulatory requirements. By providing an adaptable solution for supervision, control and data acquisition SCADA can help companies successfully navigate such hurdles while driving their success and driving growth and success forward.