A Chinese Company Can 3D-Print Ten Houses In Less Than a Day

Apr 04, 2014 20:08

Architects in Amsterdam have started work on the world's first completely 3D printed house. It will take three years to finish and the investment is pretty high. On the other end of the world, in Shanghai, a company claims to have printed ten houses with inexpensive industrial scraps. They did this all in less than a day.

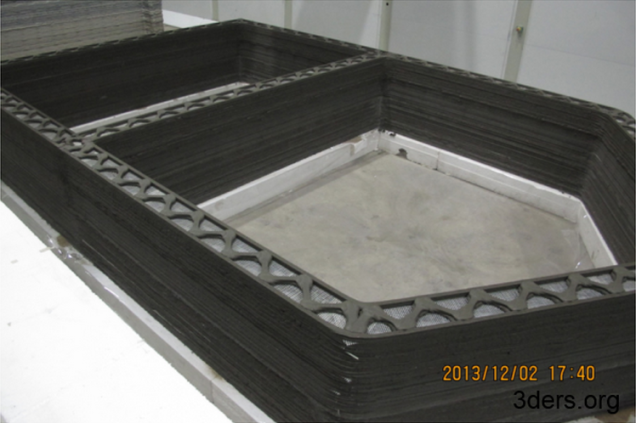

In Shanghai, its 3D printers measure 490 feet long, 33 feet wide and 20 feet deep. The Chinese company WinSun Decoration Design Engineering Co prints with concrete aggregate "made in part from recycled construction waste, industrial waste and tailings.". Each home will cost less than $5,000 to make.

WinSun prints its houses in pieces, and fully assembles them on site according to 3Ders.org's recent report. Like a mix of 3D printing and prefab techniques.

Amsterdam's one on the other hand, details every room, piece of furniture and more. Very different from Shanghai's techniques.

But if WinSun's techniques turn out to be true, it may actually be more efficient to do it their way. The process would be perfect for fabricating homes for the impoverished and displaced.

[A|N Blog; 3Ders.org]